Blog

904L Steel Properties Applications Benefits Explained

I first came across 904L steel and was really curious about why people call it a super austenitic stainless steel. This isn’t your regular stainless steel – 904L is like a secret weapon for industries that absolutely need corrosion resistance. What’s so special about 904L steel? It’s got this perfect mix of nickel, chromium and molybdenum that makes it super resistant to acids and chlorides. Whether it’s sulfuric acid in chemical plants or saltwater in the ocean, 904L holds up great where other steels would fail.

Table of Content

Chemical Composition Breakdown

The secret behind 904L steel starts with its special chemical makeup. With 19-23% chromium, 23-28% nickel and 4-5% molybdenum, this alloy really fights corrosion well. All that nickel gives 904L its structure, and the molybdenum helps prevent pitting and crevice corrosion. The 1-2% copper is the special touch that makes it extra resistant to sulfuric acid.

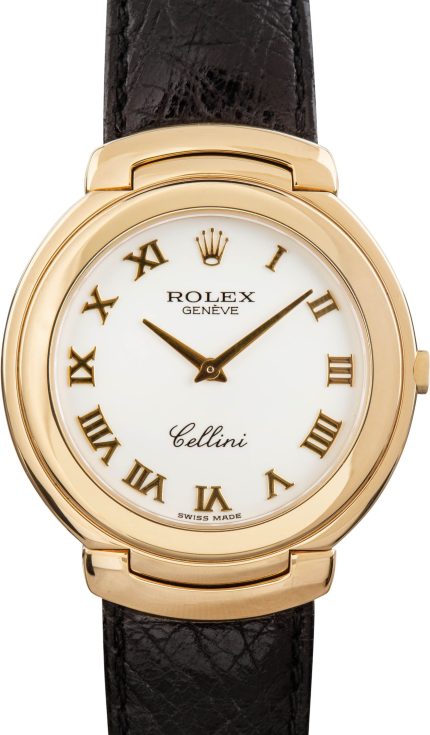

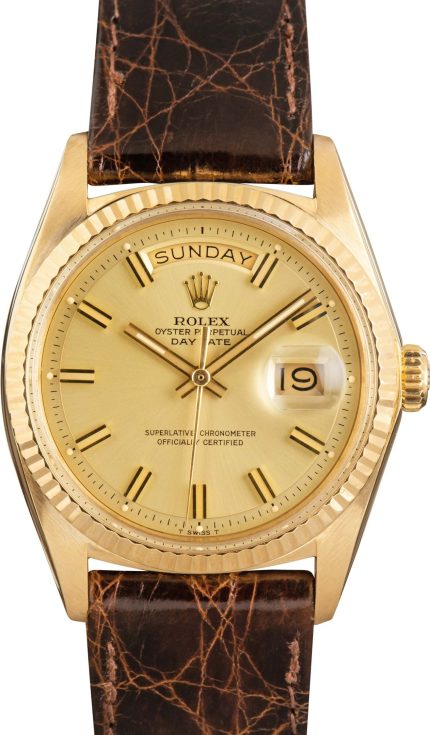

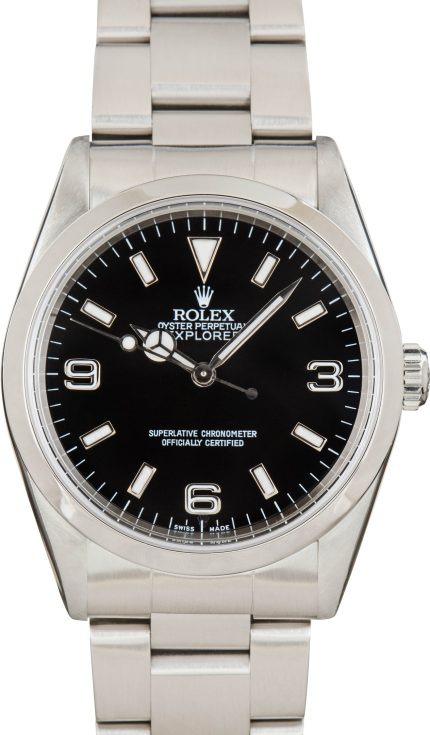

Recommended Products

You might be interested in these products

What makes 904L different is it has very little carbon – only 0.02% max. This means when you weld it, it keeps its corrosion resistance better in the heated areas. The small amount of nitrogen (up to 0.1%) helps keep the structure stable and makes it stronger. This perfect balance is why 904L steel works so well in really tough conditions.

Key Material Properties

904L isn’t just great against corrosion – it’s also really strong mechanically. It’s got great strength numbers – 490-690 MPa tensile and at least 220 MPa yield strength. It can stretch at least 35% before breaking, so you can shape it without worrying about cracks.

It handles heat pretty well too. It stays strong up to around 400°C, and doesn’t melt until 1300-1390°C. It expands a bit more with heat than regular stainless steel, so designers have to keep that in mind for hot uses. It’s not great for conducting electricity though – about 85 μΩ·cm resistance.

904L vs Other Stainless Steels

Comparison with 316L Steel

When people ask why pick 904L over 316L, I say it’s like comparing a race car to a minivan. Both work, but 904L is on another level. 316L has 16-18% chromium and 10-14% nickel, but 904L has more of these alloys, making it way better against acids and saltwater.

But 904L costs way more – usually 3-5 times the price of 316L. For really important uses like drug making or ocean systems, the extra cost is worth it because it lasts longer and needs less fixing. I’ve seen 904L parts in seawater last for decades, while 316L would need replacing every few years.

Comparison with Duplex Steels

Duplex steels like 2205 are another option – they’re strong and resist corrosion well with their two-part structure. But 904L is way better against strong acids like sulfuric and phosphoric – even duplex steels can’t match it there.

On the other hand, duplex steels handle stress cracking better and are stronger. Which one to pick depends on what you’re using it for. At one chemical plant job, we used 904L for acid parts and duplex steel for the stronger structural pieces.

Manufacturing Process

Melting and Casting Techniques

Making 904L starts in special electric furnaces where they melt the ingredients just right. A lot of people don’t know that good 904L needs extra refining steps like AOD or VOD processing. These methods fine-tune the carbon and clean out impurities.

When casting, they watch how it hardens carefully to keep the metals mixed right. Now they mostly use continuous casting instead of old ingot methods, which makes the steel more consistent. I’ve seen factories use magnetic stirring while casting to improve the steel’s structure – pretty cool how tech makes this great material even better.

Forming and Fabrication Methods

You’ve got to handle 904L differently than regular stainless steel. Because it’s got more alloys, it gets harder faster when you work it, so you need more power to shape it. When bending it, make the curves wider than you would with 304 or 316 steel to prevent cracks.

Cutting 904L can be tricky because it’s so tough. You need really sharp tools at the right angle and lots of coolant. Most shops use carbide tools and don’t cut too fast to save their tools. Funny thing – unlike most stainless steels, 904L actually cuts a bit better when you go faster.

Corrosion Resistance

Acid Resistance Performance

904L really proves itself in acidic conditions that would ruin other steels. It’s amazing against sulfuric acid – under 50% concentration and 40°C, it corrodes less than 0.1 mm per year. I’ve used 904L for phosphoric acid evaporators where it did better than costlier nickel alloys.

The copper helps against certain acids, and the molybdenum stops pitting in salty water. But for nitric acid, regular 304L often works better because 904L’s extra alloys can cause problems between grains.

Chloride and Seawater Resistance

Boat engineers really like 904L, and for good reason. Its PREN rating of 35-40 makes it way better than normal stainless steels. In regular seawater, 904L barely corrodes at all, even in tight spots where 316L would pit quickly.

One job I’ll never forget was putting 904L pipes in a seawater cooling system. After five years, the 904L pipes still looked new, while the old 316L pipes had needed several replacements in that time. The customer saved 70% on maintenance costs, even though the pipes cost more upfront.

Welding 904L Steel

Recommended Welding Techniques

Welding 904L needs careful planning, but it’s not as scary as people think. The trick is keeping the welded area resistant to corrosion. I always say to use low-heat methods like TIG or plasma welding with the right 904L filler wire.

You don’t need to preheat 904L, and keep passes under 150°C to avoid big grains forming. Always use argon on the back side for the first weld to stop oxidation. A good trick is using trailing shields to protect the weld until it cools under 400°C.

Post-Weld Heat Treatment

Unlike other stainless steels, 904L usually doesn’t need heat treatment after welding. But for really tough conditions, heating to 1100-1150°C then quick cooling can bring back its best corrosion resistance.

They usually don’t stress relieve 904L because it can cause sigma phase problems at some temps. I looked at some early 904L heat exchanger failures where bad stress relief caused sigma phase issues, ruining corrosion resistance. The fix was easy – just skip that unneeded heat treatment.

Industrial Applications

Chemical Processing Equipment

About 60% of all 904L used worldwide goes to chemical plants. Because it resists sulfuric, phosphoric and acetic acids so well, it’s perfect for reactors, heat exchangers and pipes. I recently worked on a sulfuric acid concentrator where 904L was specified for all wetted parts – after ten years, the equipment shows minimal wear.

Pharmaceutical applications are growing too, where 904L’s cleanability and corrosion resistance meet stringent hygiene requirements. Its non-reactive nature ensures product purity isn’t compromised. One vaccine manufacturer reported zero contamination issues after switching from 316L to 904L for critical process equipment.

Marine and Offshore Uses

In offshore oil and gas production, 904L is the material of choice for seawater handling systems. Its resistance to chloride-induced stress corrosion cracking makes it reliable for pumps, valves, and piping. I’ve seen 904L used in desalination plants where it withstands both the corrosive seawater and the aggressive cleaning chemicals.

Shipbuilders increasingly specify 904L for critical seawater systems. One naval architect shared that using 904L for ballast water piping eliminated the corrosion issues that plagued their previous builds. The initial cost premium was offset by reduced dry-docking time for repairs.

Cost Considerations

Price Factors and Market Trends

904L’s price fluctuates with nickel and molybdenum markets, as these account for much of its cost. Currently, 904L costs about $8-12 per pound for plate material – roughly 3-5 times more than 316L. However, when you factor in total lifecycle costs, 904L often proves more economical for demanding applications.

An interesting trend I’ve noticed is increasing availability of 904L in various product forms, which has helped moderate prices. Ten years ago, you might wait months for 904L pipe; now many stockists carry inventory. The growing adoption in pharmaceutical and food processing is also driving economies of scale.

Lifecycle Cost Analysis

When evaluating 904L versus cheaper alternatives, I always recommend a thorough lifecycle cost analysis. One chemical plant calculated that while 904L piping cost 4 times more initially than 316L, it lasted 8 times longer with virtually no maintenance. Factoring in downtime for replacements, the 904L system saved over $2 million across 15 years.

For seawater applications, the math is even clearer. A marine engineer once showed me calculations proving that 904L’s superior performance actually made it cheaper than 316L within seven years, considering replacement costs and operational disruptions.

Maintenance Best Practices

Cleaning and Passivation

While 904L is highly corrosion resistant, proper maintenance extends its service life even further. Regular cleaning with mild alkaline or neutral detergents prevents buildup that could create crevice corrosion sites. Avoid chloride-containing cleaners that could induce pitting.

Passivation with nitric acid (20-50% concentration) enhances the passive layer, especially after fabrication or welding. One plant manager reported a 30% reduction in corrosion incidents after implementing routine passivation of their 904L equipment. However, avoid hydrochloric acid pickling as it can damage 904L’s surface.

Inspection Techniques

Even with 904L’s excellent performance, regular inspections are wise. Visual examination under good lighting can detect early signs of corrosion. For critical components, I recommend periodic ultrasonic thickness testing to monitor material loss.

Advanced techniques like eddy current testing work well for detecting pitting in 904L. One offshore platform uses robotic crawlers with multiple NDT sensors to inspect 904L piping – a perfect marriage of advanced materials and cutting-edge inspection technology.

Material Certifications

ASTM and ISO Standards

904L is covered by several international standards ensuring consistent quality. ASTM A240 covers plate, sheet, and strip, while A312 covers seamless and welded pipe. The equivalent EN standard is 1.4539, and UNS designation is N08904.

When sourcing 904L, I always verify it meets the relevant standard’s chemical and mechanical requirements. Reputable mills provide test certificates with each heat of material. One client avoided a potential disaster by rejecting a shipment that didn’t meet the specified molybdenum content – proof that certifications matter.

GRA Certification Importance

For critical applications, GRA (Germanischer Lloyd) certification provides additional assurance of material quality. GRA-certified 904L undergoes more stringent testing, including additional corrosion tests specific to the intended service environment.

In one case, GRA certification helped a manufacturer win a lucrative offshore contract. The client specifically required GRA-certified materials for all seawater handling systems. The certification process, while adding about 15% to material costs, opened doors to high-value projects with stringent requirements.

Future Developments

Alloy Innovations

Researchers are working on enhanced versions of 904L with even better performance. One promising development is the addition of nitrogen (up to 0.2%) to increase strength without compromising corrosion resistance. Early tests show these modified alloys could push the PREN above 45.

Another area of innovation is improving 904L’s high-temperature properties. By microalloying with elements like tungsten and niobium, scientists hope to extend its usable temperature range beyond the current 400°C limit. This could open new applications in power generation and high-temperature chemical processing.

Sustainability Trends

The stainless steel industry is focusing increasingly on sustainability, and 904L is part of this movement. Its long service life and recyclability make it environmentally favorable. Some mills now offer 904L with up to 95% recycled content without compromising quality.

I’m particularly excited about developments in 904L powder for additive manufacturing. This could revolutionize how we fabricate complex corrosion-resistant components, reducing material waste and enabling innovative designs impossible with traditional manufacturing.

Conclusion and Call to Action

904L steel represents the pinnacle of austenitic stainless steel technology, offering unparalleled corrosion resistance in the most demanding environments. While its initial cost is higher than standard grades, its performance and longevity often make it the most economical choice over the long term.

If you’re facing corrosion challenges with current materials, I strongly recommend evaluating 904L. Consult with materials engineers to determine if it’s suitable for your specific application. Many users are surprised to discover that switching to 904L actually reduces their total costs while dramatically improving reliability. The next time corrosion threatens your operations, remember – 904L might just be the superhero material you need.

FAQ About 904L Steel

What makes 904L steel different from regular stainless steel?

904L contains significantly higher amounts of nickel, chromium, and molybdenum than standard 300-series stainless steels. This enhanced alloy content gives it superior resistance to corrosive environments, particularly against acids and chlorides. The addition of copper further improves its performance in sulfuric acid applications.

Is 904L steel worth the higher cost compared to 316L?

In many demanding applications, absolutely. While 904L typically costs 3-5 times more than 316L initially, its dramatically longer service life and reduced maintenance often make it more economical over time. Lifecycle cost analyses frequently show 904L becoming cheaper than 316L within 5-10 years for aggressive environments.

Can 904L steel be welded easily?

904L can be welded successfully with proper techniques, though it requires more care than standard stainless steels. Recommended methods include TIG and plasma welding using matching filler metals. The key is controlling heat input and protecting the weld from oxidation to maintain corrosion resistance in the heat-affected zone.

What temperature range is 904L steel suitable for?

904L performs well from cryogenic temperatures up to about 400°C (752°F). At higher temperatures, its mechanical properties begin to degrade significantly. For continuous service above 400°C, more specialized alloys would typically be recommended.

How does 904L compare to duplex stainless steels?

904L generally offers better corrosion resistance, especially to reducing acids, while duplex steels provide higher strength. Duplex steels also typically show better resistance to stress corrosion cracking. The choice depends on the specific application requirements regarding corrosion resistance versus mechanical properties.

What industries use 904L steel most?

The chemical processing industry is the largest user of 904L, particularly for equipment handling sulfuric, phosphoric, and acetic acids. Other major applications include offshore oil and gas (seawater systems), pharmaceuticals, pulp and paper processing, and desalination plants.

Does 904L steel require special maintenance?

While 904L is highly corrosion resistant, proper maintenance extends its service life. Regular cleaning with appropriate detergents and occasional passivation with nitric acid helps maintain its protective oxide layer. Inspection for any signs of corrosion is recommended, though required maintenance is typically much less than for standard stainless steels.